Fire in the sky: the Air Launched Sortie Vehicle of the early 1980s (part 4)by Dwayne Day

|

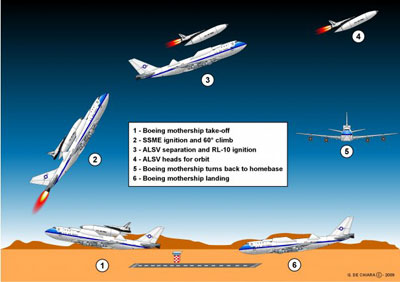

| Imagine a 747 in a 60 degree climb, with a cluster of rocket engines in its tail, passing through 11,300 meters and then pushing over into a shallow dive as a rocketplane and its large external tank separated from its back. |

The Air Force Rocket Propulsion Laboratory (AFRPL) at Edwards Air Force Base had first outlined the concept of an air-launched “Space Sortie System” in a December 1980 memo. (See: “Fire in the sky,” part 1, part 2, and part 3, in previous issues of The Space Review.) The concept was to launch a small spaceplane—probably unmanned—from the back of a 747 in a steep climb. The initial description was for a 747 burning hydrogen in afterburners fitted to its large turbofan engines to provide that climb necessary for launching the rocket. Several aerospace companies such as Convair-General Dynamics and Rockwell soon began evaluating the concept, apparently using their own funds. They determined that the idea was feasible. In 1981, AFRPL awarded a contract to rocket engine manufacturer Pratt & Whitney, who completed a study by summer of 1982 and went public with it soon after. A story about the concept appeared in Aviation Week & Space Technology, and other articles appeared in other publications. Dramatic artwork produced by Boeing showing the spacecraft separating from its 747 mothership appeared in numerous publications, even as obscure as the Buffalo Evening News. The artwork was usually accompanied by captions referring to this as “the Air Force’s new spaceship.”

According to two Pratt & Whitney engineers, Jerry Cuffe and Charles “Chuck” Limerick, who wrote about their study in 1983, normally the Air Force would hire a prime contractor to perform a study, and that prime contractor would then hire subcontractors—like rocket engine companies—to perform specific portions of the work. So it was unusual for Pratt & Whitney to be hired as the prime, with Boeing as a subcontractor. But the Air Force took this path because the engine was the primary driver in the design—and also presumably because the Air Force Rocket Propulsion Laboratory was used to dealing with rocket companies. Boeing was hired as a subcontractor because the study dictated use of a 747 and “it was also essential that the propulsion system performance sensitivities and requirements imposed by the 747 aircraft capability, vehicle weight, and mission trajectory were realistic,” the two men wrote. Vince Caluori was the Boeing program manager, and Dana Andrews was Boeing’s technical leader for the project. Other Boeing engineers who worked on it were Jim Jenkins, who served as systems engineer; Bob Conrad, who was the weights engineer; and Harrison Whippo, the propulsion specialist. In addition to determining if a 747 could carry the weight and how it would be modified, part of Boeing’s task included evaluating if a 747 could be flown in the manner required for deploying the spacecraft.

Cuffe and Limerick explained that normally, to maximize performance, they would have designed a new engine from scratch. However, one of the primary Air Force requirements was to field the “Space Sortie System” within the decade. With limited time, “a modified, existing engine was, therefore, essential,” they explained. Other modified and existing systems would also be used when possible.

Cuffe and Limerick also explained that because the delta-v requirement for reaching orbit was so high, the only viable propellant combination for the mission was liquid hydrogen and liquid oxygen. The United States at that time had only two LOX/H2 rocket engines, the powerful Space Shuttle Main Engine (SSME) and the RL10. The SSME was too large to provide a multi-engine capability in event of an engine shutdown. It also lacked the ability to throttle down its thrust substantially. The ability to throttle down is important because as a rocket burns up fuel, it gets lighter and therefore it accelerates more. If the engine thrust is not reduced, this can overstress the structure and it will break, and then… boom.

| The 747 is a big and powerful aircraft, but not when it has another massive aircraft sitting on its back. |

At the time of their study, the standard engine in production was the RL10A-3-3A, but this engine was not suitable for the Sortie Vehicle mission. With several upgrades, such as increasing the throat diameter of the engine and changing the contour of the nozzle, the RL10 engine’s thrust could be more than doubled from 73,400 newtons (16,500 pounds) in vacuum to 153,500 (34,500 pounds) of thrust. It would only operate at this high level for a short period of time after launch before throttling back to 133,000 newtons (30,000 pounds) of thrust. In contrast, the current version of the RL10, in use nearly three decades later, generates 110,000 newtons (24,750 pounds) of thrust.

The basic Sortie Vehicle would use nine of these “34.5K” RL10 engines in its tail for power. The Sortie Vehicle engines would operate for approximately 160 seconds after launch at full power, then throttle down to their 30K cruise thrust setting. They would stay at this setting until a further throttle down was required to limit the acceleration loads on the vehicle. Eventually, the vehicle would start shutting down engines, jettison its external tank, and finally only three engines would be used to push it the last little bit into orbit.

The concept of operations of the Boeing 747/Sortie Vehicle proposal, including a steep climb prior to the release of the spaceplane. (Credit: © Giuseppe de Chiara) |

Pratt & Whitney’s study originally started off with a cluster of 30K engines consisting of two rows of five RL10s, contained in a rectangular shroud that was intended to improve their performance at high altitude. As a rocket gets higher, there is less air pressure, which allows the exhaust plume to spread out. This lowers performance, so rocket designers try to contain the plume as much as possible as the air pressure gets lower and lower.

But the engineers quickly realized that as engines were turned off in order to prevent exceeding the acceleration limits, this rectangular shroud would produce inefficiencies. Because the shroud around the engines was rectangular, as an engine shut down, the other engines would be farther away from the edge of the shroud and so their exhaust would spread out and be inefficient. The shroud at the back of the vehicle would not be fully filled when less than four engines were still firing. Another problem was that with the engines all packed in closely next to each other, they could not be gimbaled to provide vehicle control capability during ascent. This also produced a longer and wider vehicle than desirable because the spacecraft had to be triangular for reentry and landing.

Once the engineers determined that they could uprate the power to 34.5K, they could eliminate one of the ten engines and change the way they were mounted at the rear of the vehicle. Rather than putting the engines in two flat rows, they produced a configuration of seven engines mounted in a circle, with two engines outboard on either side. This made for a taller, shorter vehicle. It also meant that the engines in the circle could be shrouded, increasing their performance, and the two outboard engines could be gimbaled for attitude control.

| Pratt & Whitney—an engine company, not a spacecraft company—did not devote much attention to the actual design of the Sortie Vehicle and determined the best shape primarily by what would best support the engines. |

In this new configuration, the engineers initially looked at the possibility of a cylindrical shroud surrounding the engines in a circle. The shroud would extend as the vehicle gained altitude, operating at two positions during the flight before being jettisoned. But the shroud had poor performance at low altitude. So as a next step the engineers looked at a reusable four-position extendible/retractable shroud. Both the disposable and reusable shrouds would allow for the two outboard engines to be pressure-fed with a low thrust capability.

The reusable shroud design improved performance, but not by much. At best it provided a net payload increase of 135 kilograms (300 pounds). But this came at the cost of added complexity, operational and maintenance problems, and increased difficulty of system testing during development. The engineers determined that it was a better idea to simply leave the shroud off and accept the slightly lower performance. This also allowed the outboard engines to delete the pressure-fed configuration and use the same design as the other seven engines.

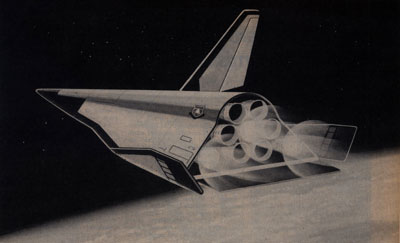

An Air Force illustration of a Sortie Vehicle reaching orbit. (Credit: USAF |

The 747 is a big and powerful aircraft, but not when it has another massive aircraft sitting on its back. With the Sortie Vehicle attached it could only reach a maximum altitude of 7,600 meters (25,000 feet). But the amount of mass that the space vehicle could inject into orbit depended heavily upon the altitude at which it separated from the 747 and the flight path angle. Also, separating the two vehicles at less than 9,100 meters (30,000 feet) would result in the Sortie Vehicle slowing down due to air drag, which would push propellants in their tanks away from the rocket engine inlets, making it hard to start them.

According to Limerick and Cuffe, although hydrogen afterburners for the 747 were possible, they did not already exist, and this would require a lengthy development program. Instead, they decided to select an existing rocket engine to mount to the 747.

As Dana Andrews remembers it, Boeing’s engineers first proposed using the Space Shuttle Main Engine “as a major performance improvement” to the craft. The SSME has over 2.18 million newtons (490,000 pounds) of thrust in vacuum. It’s a powerful thoroughbred of an engine, and even today it is arguably the highest performing rocket engine ever built. Perhaps because the idea of a 747 being powered by an SSME was such a cool one, the artwork produced by contractors for the Sortie Vehicle concept shows the 747 with one of these engines.

But Pratt & Whitney’s engineers countered that the SSME was not ideal for the job. Instead, they opted in favor of a cluster of seven RL10s at the rear of the fuselage. They would be identical to the ones used in the Sortie Vehicle but would have different nozzles. The RL10 required less than a minute of preconditioning prior to start. In contrast, the SSME required approximately 40 minutes. The RL10 cluster provided engine-out capability, reduced initial and operating costs, and “ripple start capability” that reduced the tank pressure requirements for starting compared to the SSME. They even posed the possibility of using the RL10s during aircraft takeoff to get off the ground, just like the “Jet-Assisted Take-Off,” or “JATO” rockets used to launch heavy aircraft in the 1940s and 1950s.

The aft end of the fuselage proved to be a good location for the rocket engines. The 747, like all modern jumbo jets, is pressurized, and the rear of the passenger cabin contains the end of the pressurized compartment of the plane. The pressure in the tank pushes against the back of the tank, and the rocket engines could be mounted on the other side of the tank and would push forward against the air pressure inside the tank pushing back. It was a structurally sound design.

The launch aircraft would be a modified 747-200F, the freighter version of the jumbo jet. A single large cylindrical 19,500-kilogram (43,000-pound) H2 dewar would fill most of the aircraft interior. Two smaller cylindrical dewars carrying 114,000 kilograms (250,000 pounds) of O2 would be mounted over the wing base of the aircraft. The entire craft was supposed to be capable of standing alert on a runway, perhaps for use in event of nuclear combat toe-to-toe with the Ruskies. However, it was not clear how long it would do this considering the possibility of hydrogen boiloff.

Total weight of the 747 and its Sortie Vehicle and tank at takeoff would be 390,000 kilograms (860,000 pounds), including 128,000 kilograms (283,000 pounds) of cryogenic propellants and 72,500 kilograms (160,000 pounds) of fuel for the 747’s turbofan engines. The system could place 10,500 kilograms (23,150 pounds) into a nominal 185-kilometer (100-nautical-mile) polar orbit, enabling approximately 1,360 kilograms (3,000 pounds) of “discretionary mission equipment” to be carried “on a round trip mission.”

| It was never clear what the ALSV could do that was vital to national security. |

The Sortie Vehicle’s drop tank would have a diameter of 4.32 meters (170 inches) and a length of 24.4 meters (80 feet). It would require some thermal protection due to heating caused during ascent. Because the tank would be so lightweight, it would also require support by a cradle that fully distributed the load. The tank would be jettisoned as the vehicle reached 109,000 meters (357,000 feet). Limerick and Cuffe acknowledged that they had not evaluated all of the possible options for the craft. For instance, one option, which was mentioned in the original December 1980 document that outlined the Space Sortie System, was to use a “lifting ascent” whereby the vehicle actually generated lift as it flew forward so that the engines did not do all of the work. Such a design would not have the large bulbous tank that they projected, but presumably a more wedge-shaped design capable of generating some lift of its own.

Unlike the Rockwell study (see part 3), Pratt & Whitney—an engine company, not a spacecraft company—did not devote much attention to the actual design of the Sortie Vehicle and determined the best shape primarily by what would best support the engines. Whereas Rockwell investigated both a wedge-shaped FDL-5-derived lifting-body shape as well as something that looked more like a stunted Space Shuttle design, the Pratt & Whitney design was a wedge-shaped pyramid, approximately 15.8 meters (52 feet) long and 9.1 meters (30 feet) wide and weighing about 9,100 kilograms (20,000 pounds). It had tall, angled sides, and small winglets and a single tail. The “discretionary equipment bay” would be approximately 2.5 meters (100 inches) long and increase from approximately 1.3 meters (53 inches) in diameter at the front to 1.6 meters (64 inches) in diameter at the rear. This was big enough to carry an astronaut (after all, the Mercury spacecraft was only a little larger than the ALSV payload bay). But what would a single astronaut do in such a vehicle without any equipment?

Although both the 747 and the spacecraft were reusable, like the Space Shuttle the ALSV was only partially reusable. According to Dana Andrews, although the studies showed that the vehicle could be built, the Air Force was thwarted by the cost of the external tank. Andrews said that the tank alone was estimated to cost $15 million. It was more than the Air Force was willing to pay for the ability to place only 3,000 pounds of cargo into orbit. Furthermore, at the time the Space Shuttle was subsidized by NASA, and Andrews remembers that the price for putting a payload on the more-capable shuttle was less than the cost of an ALSV tank.

There was probably another obstacle as well: it was never clear what the ALSV could do that was vital to national security. At the time, the early 1980s, it was still official US Air Force policy to retire its fleet of expendable launch vehicles like the Atlas and Delta and switch all remaining national security payloads to the Space Shuttle. Certainly it would not make sense to launch really small payloads aboard the shuttle, and so the ALSV could have provided that service. But there were no stated requirements for such a vehicle from the senior levels of the Air Force or the Pentagon. And ALSV’s other attributes, such as its ability to launch from virtually anywhere to any orbit, were not sufficiently attractive to keep the program going. Over the next several years, the Air Force continued general studies into the possibility of a quick-reaction craft that could operate either at extremely high altitudes or possibly even in low orbit. But these did not proceed to development. And no 747 pilot ever had the chance to toss a spacecraft into orbit while flying the baddest jumbo jet ever built.