Revisiting SLS/Orion launch costsby John Strickland

|

| It is hard to see how a large rocket like the SLS could possibly cost a lot less than the Space Shuttle on a per-launch basis. |

The shuttle, which consisted of two “re-manufactureable” solid boosters, an expendable external tank, and a refurbishable orbiter, cost about $1 billion per launch, based only on average annual program costs, and $1.5 billion per launch if development costs were also included, based on a 2011 study.

Several launch cost estimates for the SLS/Orion system can be made. The lowest and least believable, of $500 million per launch, is from an unofficial NASA document that does not specify if the figure includes the estimated $30-billion development cost or even the annual operating budget, exclusive of costs for specific launches. We will assume that this is their estimate of the actual minimum cost of replacing all of the rocket equipment destroyed during a successful launch. It certainly does not include annual operations costs or payload costs.

None of the new solid rocket booster casings for the SLS would be reused. At any rate, re-use via remanufacturing only saves about 20% of the cost of brand new solid booster segments. There also seems to be no effort to make the proposed advanced liquid fuel boosters reusable either.

The combined development cost of the SLS and Orion is about $3 billion a year for at least 10 years. If the program were run operationally for 30 years (similar to the shuttle), the prorated development costs (not including the financing costs that would be incurred by a private company), with one launch per year, would be about $1 billion a year. The annual operating cost of the shuttle program, needed to maintain the “standing army” required to do launch operations, was about $3–5 billion. We will assume that due to the reduced maintenance costs (there being no re-usable orbiters to maintain), that the annual operating budget would be at about $2 billion.

I had recently been seeing conflicting reports about the cost and ability to reuse the Orion spacecraft. The Orion capsule is theoretically reusable, but will land in salt water due to the decision of the designers not to use a dry land (pusher type) launch abort and landing system that would use up only 1/40th of the vehicle’s entire 20 metric ton mass and instead choosing to use an old-fashioned expendable puller escape system instead. The more modern pusher system could have been used as a landing system and an abort system. It is similar to those being designed for use on the Dragon capsule, the CST-100, and the Dream Chaser, and these are reusable. The SLS launch abort system and the Orion’s service module are both expendable.

The penetration of the salt water inside the unpressurized portions of the Orion capsule makes it unlikely that it can be re-used, as it would have to be disassembled and rebuilt each time. The salt water probably would not penetrate inside the pressurized cabin, but could damage the outside of the cabin and all wiring going into it. It is unclear how much salt water penetration there would be.

The PICA-X materials used on the Dragon capsule have been designed to withstand entry from a return lunar trajectory and were derived from NASA-developed PICA. If the Orion could be reused, the older style heat shield used on Orion would need to be replaced after each flight.

| The current large SLS/Orion development budget of about $3 billion a year precludes any development of any other payloads for the SLS. |

Based on several external estimates, the SLS/Orion combination can be launched once a year, assuming NASA’s current limited, flat budget continues. Equipment at Michoud would probably allow two first (core) stages to be built each year. So, if we assume an annual SLS operating budget of $2 billion, with one launch per year at $1 billion for the rocket and $1 billion for the spacecraft, that brings us up to $4 billion a year, similar to the Shuttle’s operating budget. In this case, the cost of replacing the rocket and spacecraft take up a much larger portion of the total budget, and the cost of maintaining the workforce and maintaining and refurbishing the existing vehicle fleet a much smaller portion. The cost of maintaining the launch facilities would be similar. However, the operating budget is the most uncertain value.

The bill for an SLS launch, at the flight rate of one launch per year, might then look like this:

| Orion capsule with service module and escape system | $1 billion |

| SLS first stage, second stage and upper stage | $1 billion |

| Annual operating and launch facility maintenance costs | $2 billion |

| 1/30 share of development cost | $1 billion |

| TOTAL | $5 billion cost per launch |

The actual annual expenditure would be only $4 billion, but due to the currently flat NASA budget, declining due to both inflation and politics, a $4-billion share of the budget is a bigger share than the shuttle took up in the past. The $1 billion per year during the operational period that is charged to the development is a real cost, since that money was not available to develop other vehicles or equipment for an entire decade.

The current large SLS/Orion development budget of about $3 billion a year precludes any development of any other payloads for the SLS. In an article in 2012, Chris Kraft and Tom Moser point out that development of “the crewed lunar lander, a multi-mission space exploration vehicle (MMSEV), a deep space habitat, a lunar surface rover and other lunar infrastructure” are being crowded out by the SLS development effort, so that by the time the SLS would be ready to use, there would be little or no hardware for it to launch. The same would be true for any specialized hardware needed for asteroid or Mars exploration. In addition, they point out that the “the extra $4 billion to $5 billion per year needed to make an SLS-based exploration strategy work” will be unaffordable given the worsening fiscal situation. The dilemma posed by this situation is that NASA can afford to slowly develop a giant rocket, or develop payloads to launch on the rocket, but not both at the same time.

Coincidentally with my new analysis, a recent article appears to support those who have been saying that NASA cannot and will not launch the SLS very often. A June 28, 2013, article in Space News, covering an official media tour of the Michoud plant and touting its new welding equipment, seems to indicate that NASA intends to fly the SLS only about once every four years even after the rocket’s development is completed. Previously the slowest launch rate anyone predicted was every two years. Even if NASA wants to fly the SLS more often, the cost of preparing new payloads for it may still greatly limit its flight rate. The Space News article quotes Steven Squyres, chairman of the NASA Advisory Council, as saying, “We have no experience with a human-rated flight system that only flies every two or three or four years.” This then brings into question the readiness of a launch team to do safe launches at rare intervals. This is a significant issue if you remember the problems of starting up shuttle launches again after the long launch gaps after the two shuttle accidents.

Information in another unofficial schedule posted on the Wikipedia page for the SLS (current as of July 1, 2013), indicates that NASA now does not plan to complete development of the 130-ton Block II version of the SLS until as late as 2030. Estimates of the payload up to those dates are between the initial 70 tons and up to 105 tons. This also implies a stretched out program and continuing development costs for another 15 or more years.

| The US government should either decide to turn the SLS into a reusable HLV booster, or open a competitive bidding for a privately designed and built reusable HLV. |

This information radically changes the assumed cost of each launch, since now, over a presumed 28-year lifespan, starting in perhaps 2022 and lasting presumably until 2050, the rocket would be used only seven times, and for more than a third of its lifespan, not able to launch the promised 130 tons. Its $30-billion development cost would then need to be divided among the few actual launches, not over all the years of the 28-year period, and would be about $4.3 billion per launch. This share of the launch cost represents money that could have been spend on payloads in years past. The per-launch cost of the rocket now jumps from $5 billion up to about $9 billion. The continuing annual cost of maintaining the workforce that allows launches to occur are rare intervals would need to be counted as part of each launch cost. The lesson learned from the Space Shuttle era is that the manpower costs are the largest cost, which is demonstrated again here. The cost table shown above now looks very different. Note that launch prices per ton and per pound for the initial 70-ton SLS version would be almost double that for the 130-ton version.

Revised bill for one SLS launch (one launch every 4 years):

| Orion capsule with service module and escape system | $1 billion |

| SLS first (core) stage, and upper stage | $1 billion |

| Annual operating and launch facility maintenance costs | $8 billion (cost over 4 years) |

| 1/7 share of development cost | $4.3 billion |

| TOTAL | $14.3 billion cost per launch |

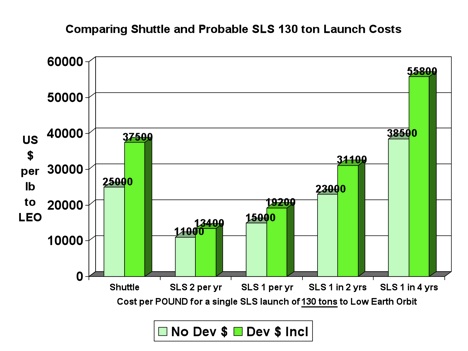

So, compared to the shuttle, how much would an SLS launch (of 130 tons) cost per pound if it was launched at several different conceivable rates. I have put the numbers for the intermediate launch frequencies into the figure below. Prices per pound for the SLS would be 86% higher if it launches only 70 tons.

|

So the full-sized payload version of the SLS is slightly cheaper that the shuttle at one launch per year, due to the roughly five-fold increase in actual payload compared to the shuttle when it was used as a payload delivery system. This means that the SLS launched once a year will be six times as expensive as a Falcon 9 expendable launch and 15 times as expensive as a Falcon Heavy expendable launch.

The upshot is that the situation described by my previous assessment (and those of many others) remains accurate and in some respects is worse:

The US government should either decide to turn the SLS into a reusable HLV booster, (something that a private company with a tiny fraction of the US government’s capabilities is already trying to do), or open a competitive bidding for a privately designed and built reusable HLV. Working on a reusable HLV, even one based on the SLS, would not reduce the current work force, and once it was ready for flight, it would enable a great expansion of the space work force in other areas such as spacecraft development and construction. We really do need a HLV booster to launch very wide payloads (up to 15 meters in diameter), but we cannot afford to launch such payloads on an expendable booster.

Some of the money being spent on the SLS/Orion program may not be wasted, such as the programs to redevelop modern versions of large Apollo-era rocket engines that could be used on a variety of other vehicles.

The fact that, in spite of my best efforts, the estimates used in this reassessment of the SLS may or may not be accurate or fair is countered by the reality that getting hard flight cost, hardware construction cost, and annual operational cost numbers out of NASA officialdom is impossible. In no way should criticism of a NASA program decision should be interpreted as criticism of NASA employees, especially as this program is, to a large degree, being forced on NASA by the Congress.